Patent drawings are more than just illustrations — they’re critical tools for visually communicating the structure and function of an invention. Whether you’re preparing mechanical components, product designs, or utility models, hatching and shading in patent drawings play a crucial role in ensuring clarity, compliance, and approval by patent offices like the USPTO.

In this technical guide, we’ll break down the importance of depth representation, outline official shading USPTO rules, explore cross-sectional techniques, highlight common errors, and share top software for shading like AutoCAD and SolidWorks.

For professional, USPTO-compliant illustrations, explore Graphizon’s Patent Drawing Services to ensure your drawings meet the highest quality and regulatory standards.

Importance of Depth Representation

Unlike standard illustrations, patent drawings must provide a clear, precise, and legally accurate representation of the invention. Depth representation through shading and hatching helps distinguish surfaces, contours, and cross-sections, ensuring that the drawings are easily understood by examiners, attorneys, and manufacturers.

- Enhances Visual Clarity: Proper shading defines curved surfaces, while hatching clarifies flat and cross-sectional planes.

- Supports Legal Interpretation: A well-shaded drawing strengthens the patent’s enforceability by ensuring every element is accurately depicted.

- Improves Examiner Comprehension: Patent examiners rely on shading cues to understand how different parts interact. Clear representation speeds up examination and reduces office actions related to unclear drawings.

Pro Tip: Consistency is key. Maintain the same shading angles, line spacing, and thickness across all figures. This professional finish is exactly what we deliver at Graphizon.

USPTO Rules for Shading & Hatching

The USPTO’s official guidelines and 37 CFR § 1.84 outline how shading and hatching should be applied to ensure uniformity and legal precision.

Shading Rules

- Surface Shading: Allowed in utility applications to indicate spherical, cylindrical, or conical shapes.

- No Obscuring: Shading must not obscure reference characters or structural lines.

- Consistent Style: Apply shading consistently across all figures.

- No Color Representation: Shading cannot indicate color or black surfaces (except in design drawings).

Hatching Rules

- Standard Angles: Hatching lines are typically drawn at 45°, but different angles (e.g., 30°, 60°) may be used to distinguish adjacent parts.

- Uniform Spacing: Lines should be evenly spaced and clear, avoiding overly dense shading.

- Cross-Sectional Representation: Hatching indicates material cut in cross-section.

- Avoid Confusion: Hatching should never intersect reference numbers, and blank spaces should be left where numbers or symbols are placed.

The USPTO specifically recommends using thin, clean, black lines for hatching and shading, ensuring the drawing remains clear and reproducible in black and white.

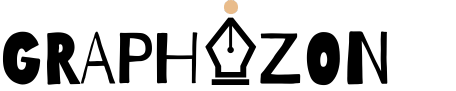

Cross-Sectional Techniques

Cross-sectional patent illustrations are essential for revealing internal components that can’t be shown in exterior views. Proper hatching techniques make these areas visually distinct and technically accurate.

- Define the Cutting Plane: Indicate it in one view with a cutting line and arrows showing the direction of sight.

- Create the Section View: Expose the internal features in a separate sectional view.

- Apply Hatching: Use different angles for adjacent parts to distinguish them clearly.

- Leave Blank Spaces: Uncut areas must remain blank to avoid misinterpretation.

- Reference Numbers Placement: Place them outside hatched areas with clean leader lines.

At Graphizon, our experts follow global patent office conventions for cross-sections to ensure compliance and reduce rejections.

Common Errors in Shading

Even experienced drafters can make errors that lead to USPTO objections or rejections. Avoid these common pitfalls:

- Inconsistent Line Work: Mixing line thicknesses, angles, or spacing between figures breaks uniformity.

- Overlapping Text and Shading: When shading intersects reference numbers, it reduces legibility.

- Using Shading for Color: Not allowed in utility drawings.

- Excessive Darkness: Dense hatching makes reproduction difficult.

- Flat Shading on Curved Surfaces: Misrepresents shapes, especially critical for design patents.

Quick Fix: Print the drawing in black and white at actual size. If details are lost or unclear, revise the hatching/shading. This quality control step is a standard part of Graphizon’s drawing process.

Software for Shading (AutoCAD, SolidWorks)

Modern drafting depends on advanced CAD software to produce USPTO-compliant drawings efficiently. Two of the most trusted tools are AutoCAD and SolidWorks.

AutoCAD

AutoCAD is widely used for precise line work and standardized hatching.

- Precision hatching tools with control over pattern, angle, and scale.

- Layer management to separate shading, hatching, and outlines.

- Customizable hatch patterns for different materials.

- Vector outputs that maintain line integrity for patent office submissions.

Learn more about AutoCAD’s hatching features from AutoDesk’s official documentation.

SolidWorks

SolidWorks offers automated sectioning and shading ideal for complex components.

- Automated Section Views: Generates section views with correct hatching angles for each part.

- Surface Rendering: Helps accurately shade complex curves before conversion to line art.

- Template Libraries: Maintain consistency across multiple drawings.

- High-Resolution Exports: USPTO-accepted formats like PDF or TIFF with clean lines.

Explore SolidWorks drafting tools in SolidWorks Official Documentation.

At Graphizon, we leverage both AutoCAD’s precision and SolidWorks’ automation to deliver drawings that are technically flawless and legally robust.